Interested in CW (Morse code)?

The cost got you a little turned off?

Here is a simple to make, inexpensive (zero $), keyer that works really well.

The cost of getting into CW has escalated in the past few years. A keyer, the device that creates the code is easily over $100 and the key, the paddle device you touch to activate the dits and dahs in the keyer will set you back well over $100. You can keep the keyer’s cost down by home-brewing from a kit such as the CMOS III mentioned in the CW Article. What about the key? They are complicated devices that it looks like only a skilled craftsman with a well appointed shop would even think about attempting. Well that is not true. Here is a design that anyone can make for almost zero dollars that will have you keying with the best of them.

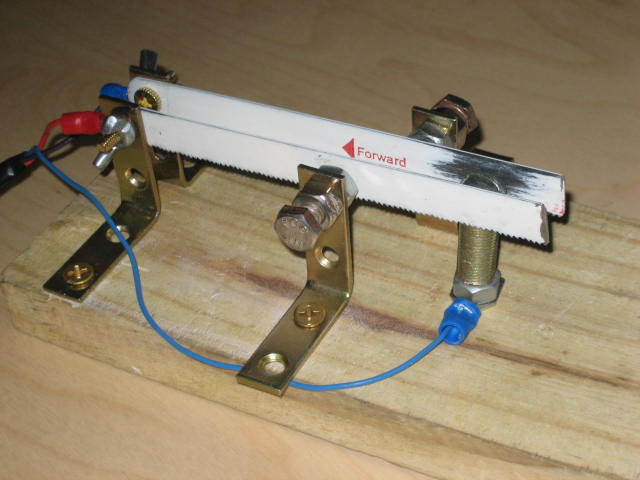

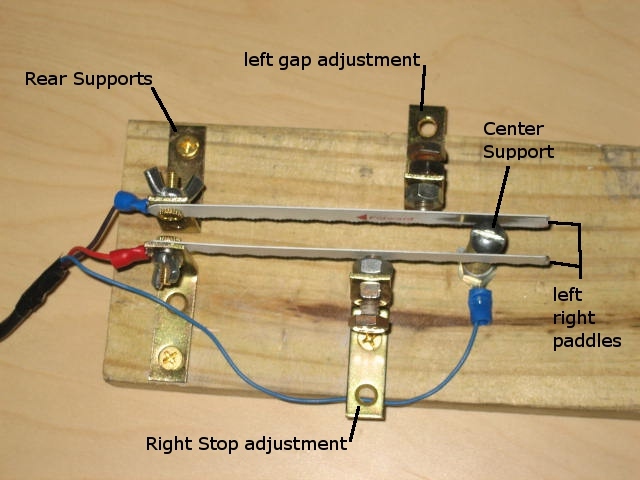

The Hackey:

The Hackey is built using a 12″ hacksaw blade cut in half that act as the paddles and the springs. This is a prototype that has performed much better than expected. It is sensitive, light on the fingers and fully adjustable.

Refer to the following diagram:

- Rear Supports: 1.25: corner brackets. Holds the back of the paddle and dit and dah connections to the keyer. Spacing is determined by the center support width. The paddles should run parallel. Twisting outward will add tension.

- Left / Right Gap Adjustments: 1.25″ corner brackets. Drilled out to fit large bolts that adjust the key gap. Large bolt makes it easier to adjust. use two nuts to hold adjustment. Self-locking nuts epoxied to the brackets would work just as well. The two gap adjustments on the prototype are staggered to see if the position on the paddles makes a difference. If placed too far from the center support the paddles will vibrate making keying difficult. From about half way between the rear and center support to the center support does not seem to make much difference.

- Center Support: This is the common connection to the keyer. It will determine the distance between the paddles. The prototype uses a 2″ x 1/4″ bolt. The head is ~7/16″. This support must be sturdy so the when one paddle is pressed it does not push the center support over into the other paddle. The nut on the bottom is recessed and a 1″ lamp nipple to add stability.

- Paddles: Hacksaw blades, the prototype uses “Nicholson” Bi-Metaloy 18TX12″ cut to 5″. The teeth and paddle ends are sanded smooth and the paint removed at the rear and center supports. Corrosion is a concern without an immediate solution.

- Connector: 2 conductor shielded wire is used to a stereo phono plug.

That’s it. Mount it all on a scrap piece of wood or other non-metallic substance. Adjust the gaps to your liking and enjoy.

Improvements etc:

- Place this onto a nice piece of wood with brass screws… clean it up.

- Improve the gap adjustments.

- Corrosion resistance for the contacts.

- Try a junior version. 2 to 2.5″ long blades with no gap adjustments. Adjust the gap by rotating the rear supports. Should make a neat small key.